Tel:0513-81903181

Email:info@cop-nb.com

Address:Ningbo Petrochemical Economic and Technological Development Zone

Tel: 0513-81903181

Email: info@cop-nb.com

1. Product Introduction

HTL series is a family of cyclo olefin polymer (COP) optical grade thermoplastic resin products under the CCOP® brand of huanxiting, which is a dedicated material developed for high-precision optical components and high-frequency electronic devices.

The series covers models such as HTL-210/420/430/450/510/520, with the core features of integrated "precision optical performance, extreme environmental stability, and processing adaptability", which are three core advantages, and is a dedicated basic material for high-precision optical / electronic parts in the fields of automotive, consumer electronics, and optoelectronic equipment.

2. Application fields

The performance characteristics of the HTL series are highly matched with the core needs of different scenarios, and the specific application fields and adaptation logic are as follows:

Vehicle optical system:

Vehicle / surround view camera lenses

Adaptation characteristics: low water absorption (<0.01%); high heat resistance (Tg 120℃~160℃), ensuring the dimensional stability and optical accuracy of the lens in the high temperature and high humidity environment of the car cabin.

Electronic optical components:

AR/VR display lenses, viewfinder prism

Adaptation characteristics: High transparency (92% light transmission) + stability of refractive index / Abbe number, ensuring clarity of the display image, color consistency and visual immersion.

Projectors & Optoelectronic Devices:

Projector lenses, LBP Fθ lenses, LED lenses

Adaptation characteristics: low impurity + precise optical characteristics, avoiding light scattering / distortion, enhancing imaging / light efficiency.

General optical components:

Optical mirrors, diffraction gratings

Adaptation characteristics: high transparency + dimensional stability, ensuring long-term consistency of optical performance.

3. Product characteristics

The core features of the HTL series are designed around "High-precision optics + environmental stability", as follows:

Ultra-low water absorption:

Parameter: water absorption < 0.01% ( lowest grade in plastics);

Technical value: excellent dimensional stability in high humidity environments, no bending / deformation of molded parts, ensuring the assembly accuracy and performance consistency of precision optical components.

High transparency:

Parameter: full light transmission of 92%;

Technical value: Matches the transparency of acrylic resins (PMMA), meeting the high-light transmission requirements of optical components.

Low-density characteristics:

Parameter: the ratio is only 1.01;

Technical value: Significantly lighter than many engineering plastics, contributing to the lightweight design of optical components.

High heat resistance:

Parameters: glass transition temperature (Tg) of 120℃~160℃;

Technical value: It can adapt to medium and high temperature working conditions, avoiding material softening and deformation.

Low dielectric constant:

Parameters: low dielectric constant + low dielectric loss (at the highest level in thermoplastic resins, comparable to PTFE);

Technical value: Adapt to the needs of high-frequency electronic signal transmission, reducing signal attenuation.

Low impurities:

Parameters: extremely low impurity content;

Technical value: belongs to environmental protection resin, avoiding optical parts from impurities to produce light scattering, imaging distortion.

Precision optical characteristics:

Parameters: excellent stability of refractive index and Abbe number;

Technical value: The imaging accuracy requirements of the adapted lenses and other high-precision optical components ensure the consistency of visual effects.

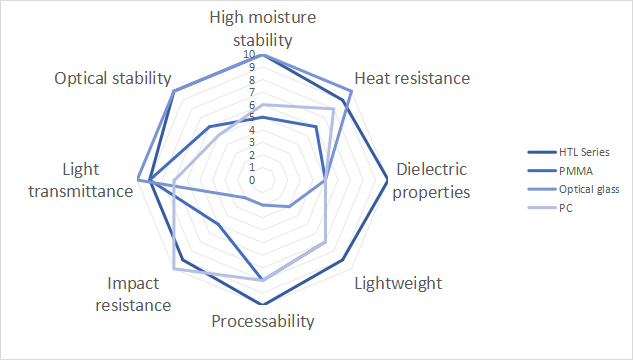

4. Comparison of the advantages of other materials

With the materials commonly used in the field of optics (PMMA, optical glass, PC) as a reference: